Client

Category

Equipment ServicingAbout This Project

Based on proved reserves and production, ConocoPhillips is the largest independent oil and gas exploration and production company in the world. With headquarters based in Houston, Texas ConocoPhillips has over 19,000 employees and assets based in 27 countries.

ConocoPhillips Australia is the operator of the Bayu-Undan facility located in the Joint Petroleum Development Area (JPDA) of the Timor Sea.

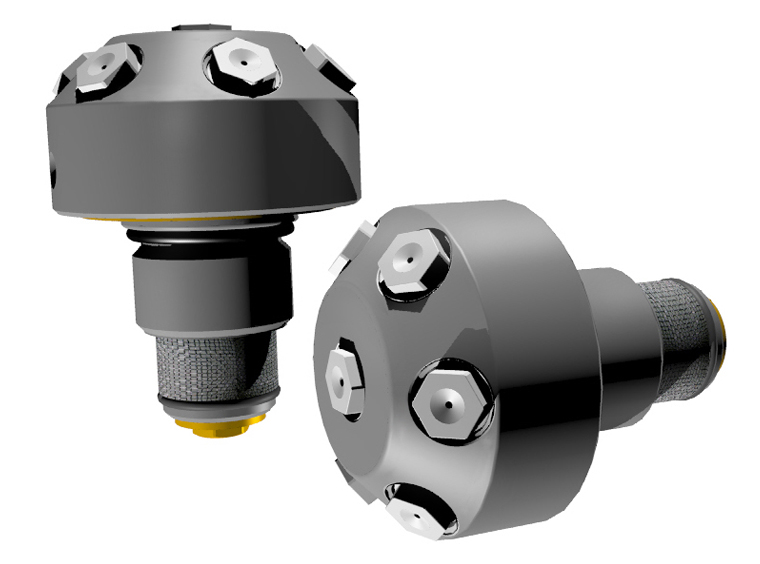

Antelope Engineering were contracted to carry out facility wide surveys of the Marioff HI-FOG® water mist fire protection systems currently protecting critical machinery on the three platforms in the Timor Sea. This project involved comprehensive strategic planning, significant logistical challenges and detailed scheduling requirements.

Antelope Engineering supplied OEM certified (TBOSIET, HUET) personnel for the offshore work and after successfully completing the surveys and the orders for upgrade equipment were placed, the offshore work commenced on the FSO.

By liaising effectively with the offshore operations personnel and the onshore based logistics department Antelope Engineering were able to conduct specialised upgrade and service work. This covered fifteen different HI-FOG® water mist systems that protect critical equipment such as the main power generators, flash gas compressors, standby generators and the only two sources of power on the wellhead platform.

Equipment deliveries being made to the Darwin supply base over the course of fifteen months required detailed scheduling and logistics. This ensured supply boat schedules were met, allowing tools and equipment to be available for the seven different offshore swings required to complete the work. Utilising eighteen swap-out cylinders provided by Antelope Engineering allowed for 24 to 48 hours turnaround which significantly reduced the downtime.

As part of Antelope Engineering’s commitment to through life support a complete set of spares, full service and maintenance kits, revised P&ID drawings, revised operation and maintenance procedures and staff training were provided. Ensuring the systems would be maintained as per OEM requirements.

Antelope Engineering will continue to work with ConocoPhillips in implementing a preventative maintenance schedule and by offering through life support and training.